A single cacao bean, though small, holds a world of diverse flavors and aromas influenced by its origin, variety, and production methods.

In recent years, methods like “bean-to-bar” and “single-origin” have gained recognition among chocolate enthusiasts for their ability to highlight the inherent qualities of cacao beans.

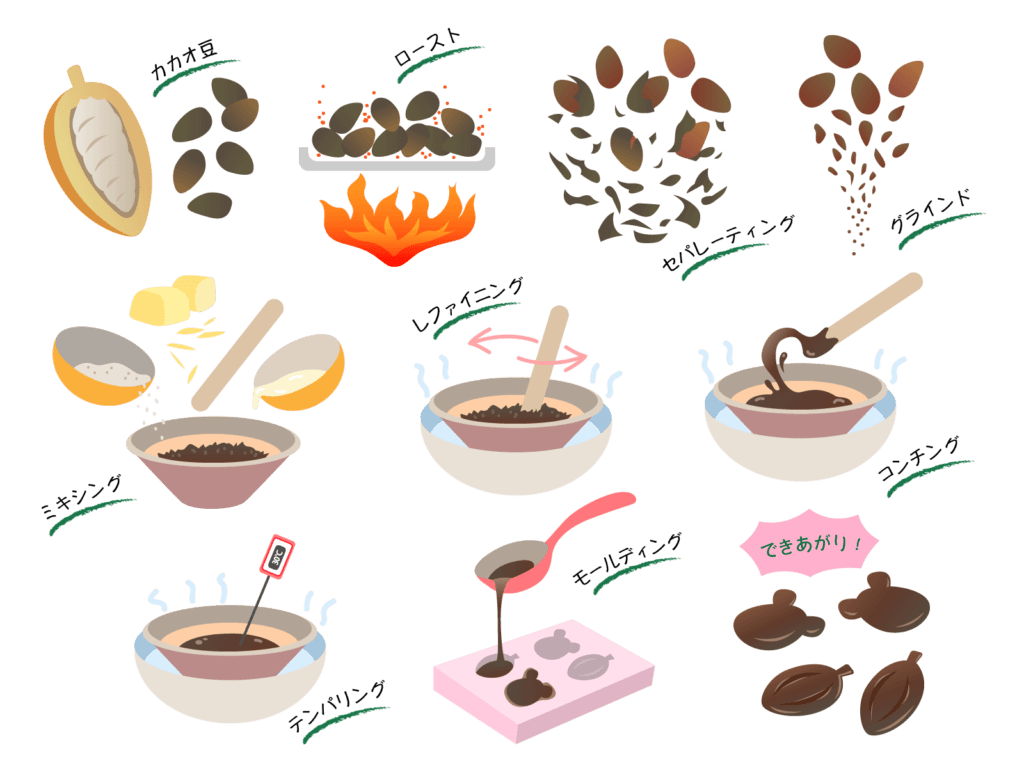

The Detailed Steps of Chocolate Production

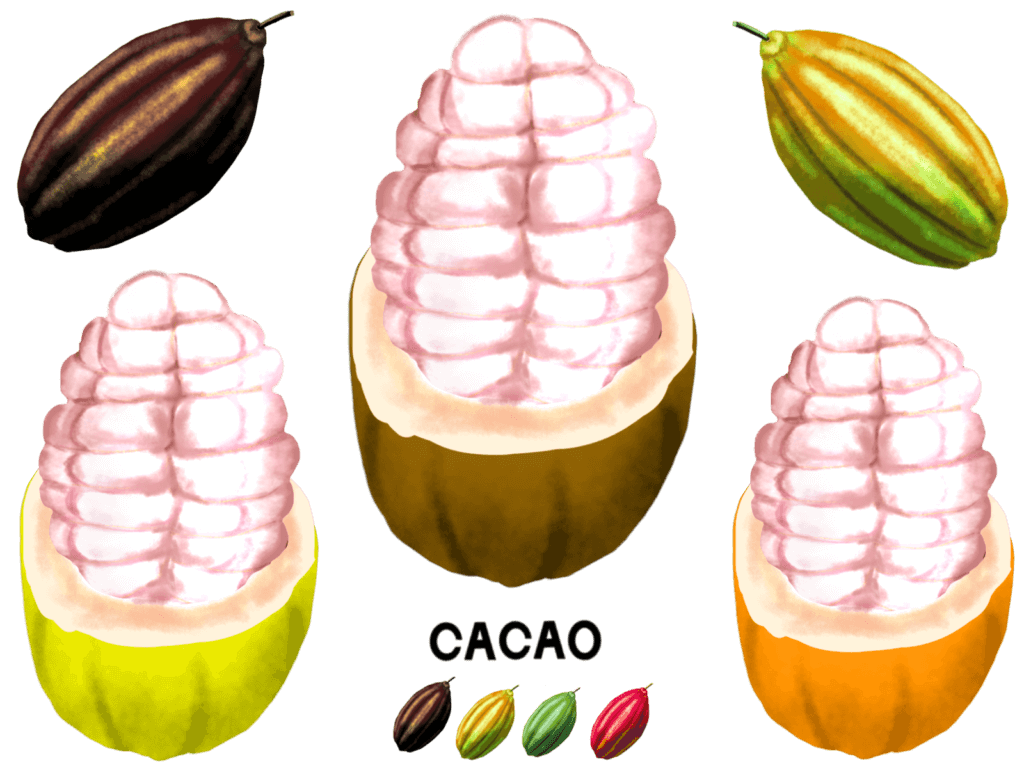

1.Cacao Bean Selection and Fermentation

Once harvested from cacao pods, the beans undergo the crucial processes of fermentation and sorting.

Key Fermentation Points:

- Gradual fermentation over 3 to 7 days

- Establishes the foundation for cacao’s signature flavors and aromas

- Insufficient fermentation results in excessive bitterness, while over-fermentation leaves an unpleasant acidity

2.Roasting the Beans

Similar to coffee, roasting dramatically alters the aroma and taste of cacao beans.

Roasting Highlights:

- Low-temperature roasting: Brings out delicate flavors

- Medium-temperature roasting: Achieves a well-balanced profile

- High-temperature roasting: Creates bold flavors with a robust, toasty aroma

3.Grinding and Conching

The beans are finely ground and kneaded for hours to achieve a smooth chocolate texture.

Key Features:

- Grinding: Transforms cacao nibs into cacao mass

- Conching: A process lasting 12 to 72 hours, refining texture and removing unwanted acidity for a velvety finish

4.Tempering Process

This final stage determines the quality and appearance of the finished chocolate.

Tempering Highlights:

- Precise temperature control: 45°C → 27°C → 31°C

- Stabilizes the crystal structure

- Affects the chocolate’s gloss, melting quality, and shelf life

Glossary of Chocolate Terminology

Terms Related to the Production Process

Conching

A process where chocolate is kneaded over a long period to achieve:

- Finer particle size for a smoother texture

- Removal of unwanted acidity

- Enhanced overall flavor and mouthfeel

Tempering

A process that stabilizes the crystal structure of chocolate.

- Requires precise temperature control

- Crucial for determining the final product’s quality, including its gloss, texture, and shelf life

Terms Related to Ingredients

Cacao Mass

A paste made by roasting and grinding cacao beans.

- Forms the foundation of chocolate

- Retains the rich, natural flavors of cacao

Cacao Butter

A plant-based fat extracted from cacao beans.

- Defines chocolate’s signature smooth melting quality

- Higher cacao butter content results in a creamier texture

Cacao Solids

The percentage of solid cacao content in chocolate.

- Higher percentages deliver a richer, more intense flavor

- Typically ranges from 50% to 80%, depending on the desired taste profile

Representative Chocolate Production Methods

Bean-to-Bar Method

This method involves handling every step of the chocolate-making process, from selecting cacao beans to crafting the final chocolate, all within a single workshop. Similar to how a chef carefully selects ingredients to create a unique dish, this process brings out the individuality of each cacao bean.

Features:

- Artisans meticulously select cacao beans and determine the best roasting and blending methods for each batch.

- Small-scale workshops ensure a handcrafted, unique flavor.

- Allows consumers to enjoy flavor differences based on the origin and harvest season of the cacao.

- Offers transparency in production and the assurance of knowing the producer’s identity.

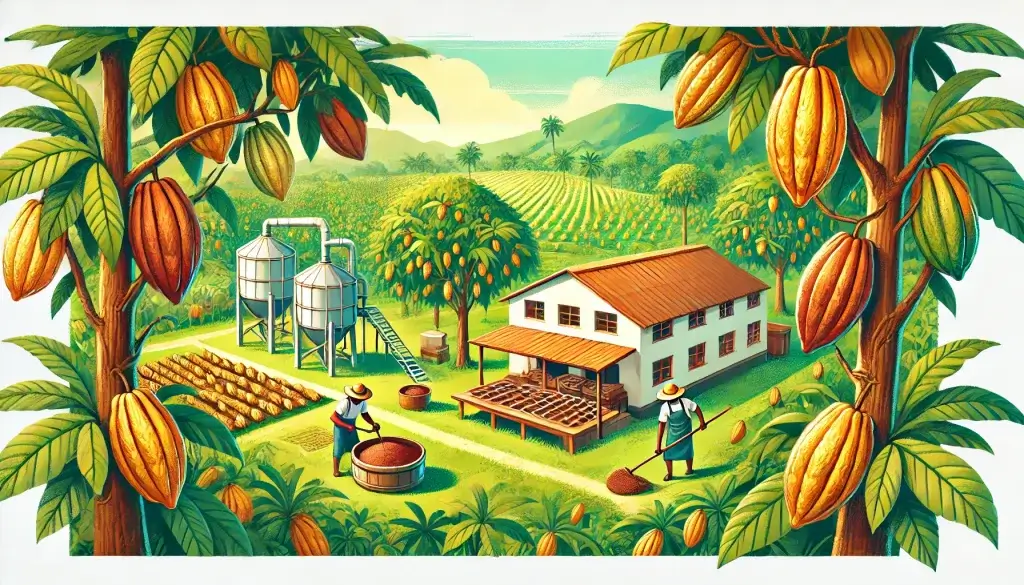

Farm-to-Bar Method

In this approach, cacao farms themselves create chocolate, akin to a farm-to-table concept. From cultivation to production, every step is managed on-site, delivering fresh, origin-direct chocolate.

Features:

- Reflects the farm’s philosophy in cacao tree cultivation, harvest timing, and fermentation methods.

- Ensures fresh flavors by processing the cacao immediately after harvest.

- Provides direct profits to farmers, embodying the ideals of fair trade.

- Offers unique flavors developed by each farm’s distinctive methods.

Single-Origin Method

Also known as “single-origin chocolate,” this method uses cacao beans sourced from a single region. Much like wine, it allows the consumer to experience the unique flavors of a specific terroir.

Features:

- Purely showcases the regional flavors of cacao from areas like Ecuador or Madagascar.

- Offers the joy of comparing taste variations based on the harvest year, even within the same origin.

- Provides a sensory experience influenced by the soil, climate, and cultivation methods of the region.

- Allows enthusiasts to explore and discover their preferred origins while learning about regional nuances.

Couverture Method

This method produces premium-grade chocolate favored by professional artisans. By using a high content of cacao butter, it achieves a smooth melt and rich flavor, ideal for high-quality confectionery.

Features:

- Contains an abundance of high-quality cacao butter for a velvety texture.

- Known for its glossy appearance and the rich aroma of pure cacao.

- Requires precise temperature control, showcasing the expertise of skilled chocolatiers.

- Preferred by professionals for creating exceptional desserts and confections.

How to Choose the Right Chocolate Production Method

- For those who want to enjoy unique flavors → Bean-to-Bar

Opt for bean-to-bar chocolate if you’re looking for distinct, handcrafted flavors that highlight the individuality of cacao beans. - For those who value a connection with producers → Farm-to-Bar

Farm-to-bar chocolate is ideal for those who prioritize knowing the farmers behind their cacao and supporting sustainable practices. - For those who want to explore regional differences → Single-Origin

Single-origin chocolate offers the opportunity to experience the unique flavors of cacao based on its specific origin and harvest year. - For those who want to enjoy professional-level baking → Couverture

Couverture chocolate is perfect for creating premium desserts, thanks to its high cacao butter content and luxurious texture.

This concise guide helps readers select the best chocolate production method based on their preferences and needs.